Custom Configuration and Build Expertise

Expertise developed over the past 50 years allows us to configure and to build virtually any coil configuration possible. In many cases, we are intimately involved in the prototyping process of the products we manufacture. Using our unique collaborative approach, we work with our customers to develop prototype that meet application requirements and financial budgets. Able Coil assists with thousands of prototypes which result in millions of coils shipped throughout the US and abroad each year.

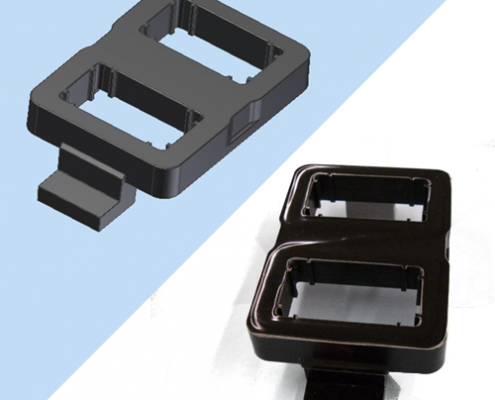

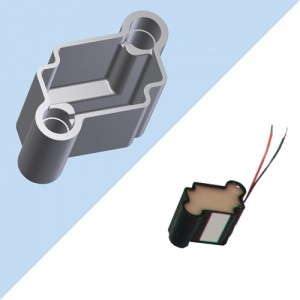

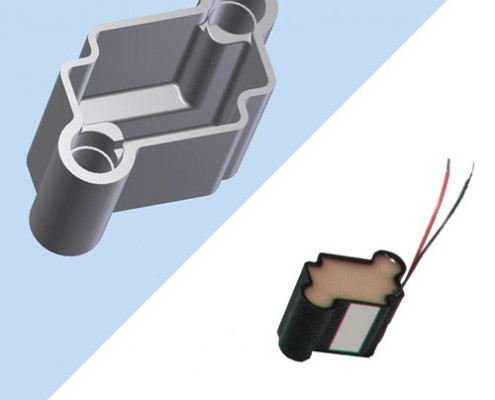

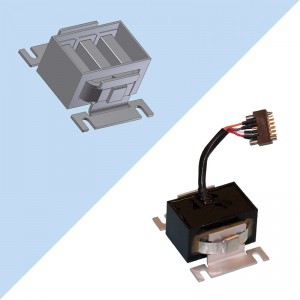

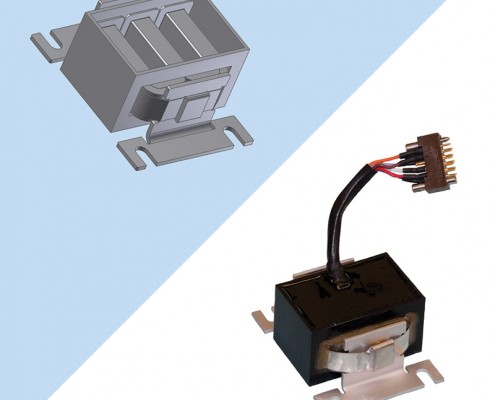

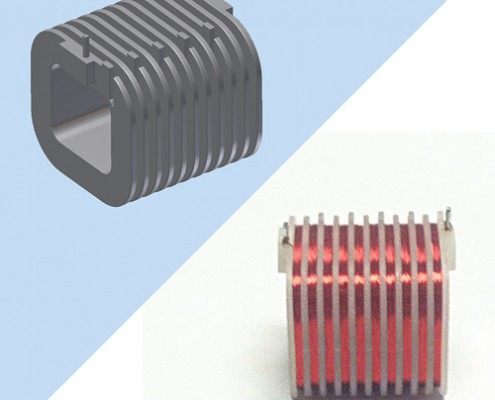

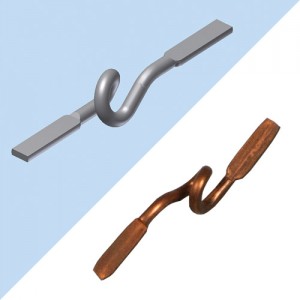

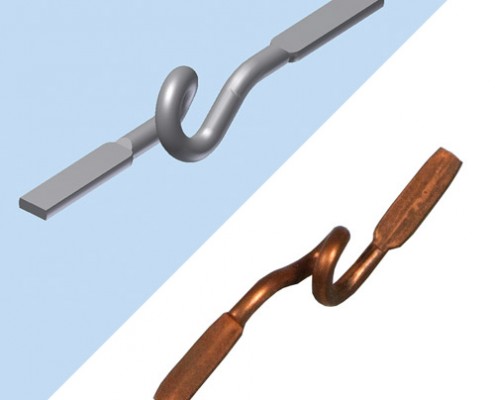

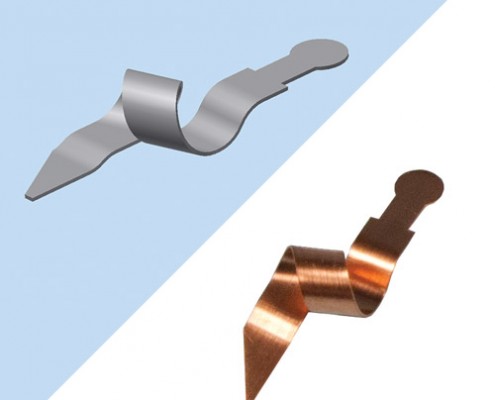

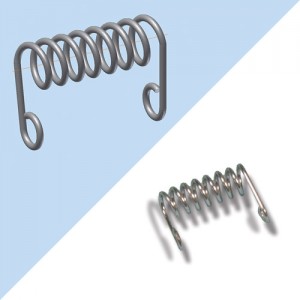

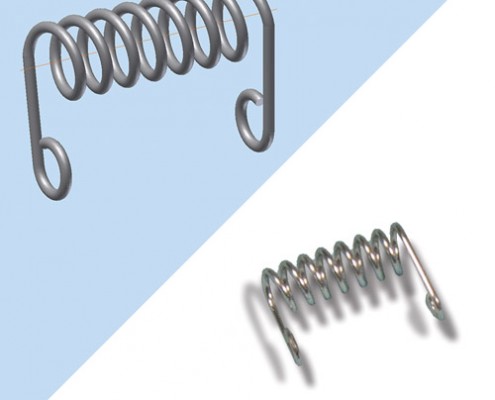

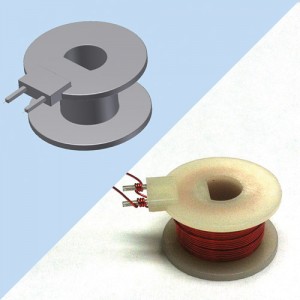

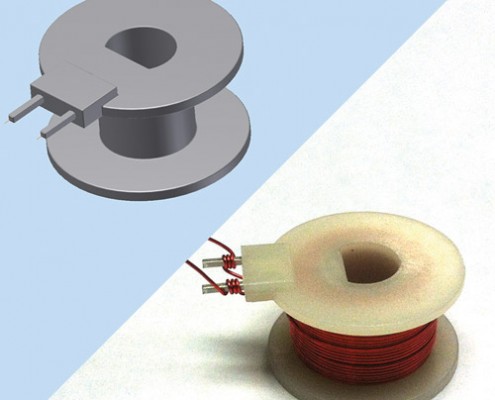

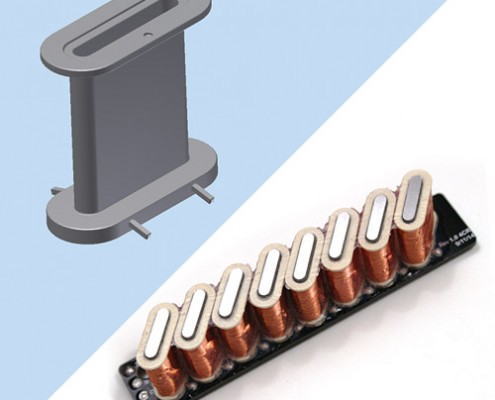

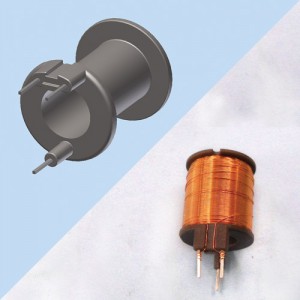

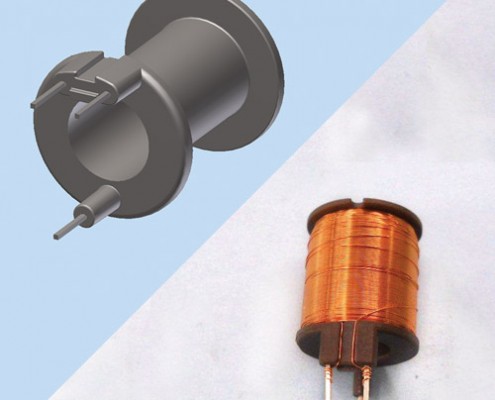

Products include bobbin wound, self-supporting, toroidal wound, universal wound (PI winding), wet wound coils, transformers, inductors, wire forms, injection over-molded coils, epoxy encapsulated assemblies, integrated devices, and many other complex geometries and assemblies. Termination methods include leads, lugs, pins, sockets, terminal blocks, connectors, surface mount headers, and various other custom solutions. We offer vacuum pressure impregnation (VPI) services for environmentally demanding applications. We typically process copper wire from #4 AWG to #56 AWG, but we also have capabilities to process aluminum and other alloys in standard and nonstandard gauges and shapes.

Our winding techniques range from hand wound to multi-spindle CNC winding machines that provide high volume precision and repeatability from lot to lot. Our insulation systems are in compliance with UL classes A (105C) through H (180C). We have extensive test and measurement capabilities including statistical process analysis and control (SPC). We use these tools to measure process capability and verify product conformance on a continual basis. Able Coil & Electronics is committed to providing quality products, on time, and at a competitive price.

Experienced Engineers

The engineering staff at Able Coil & Electronics represents years of experience in high-quality magnetic product configuration. Since 1969, our engineers have worked closely with our customers to support their product development. From electric toothbrushes to fighter jets, our products are used all over the world. We provide efficient, cost-effective solutions for the most demanding applications.

Your Development Partner

Whether building to print, or a collaboratively engineered solution, we are available for consultation with your engineering staff throughout the entire product realization cycle. Services include, application review, concept development, product configuration, 3D modeling, drafting, prototyping, qualification testing, and documented first article inspections. It is our mission to provide our customers with the best possible solutions, with minimal lead times, and affordable pricing.

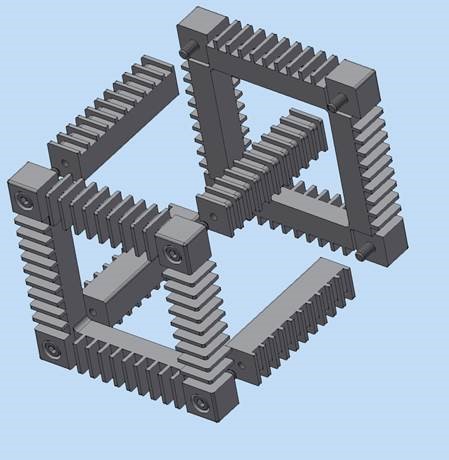

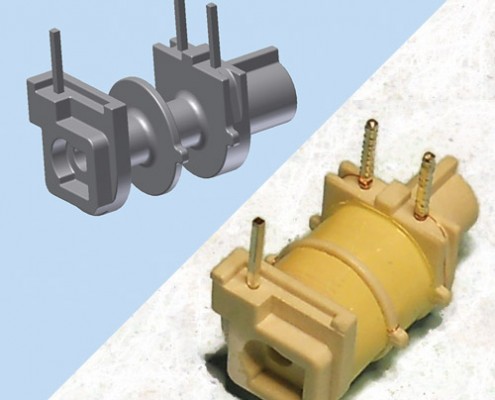

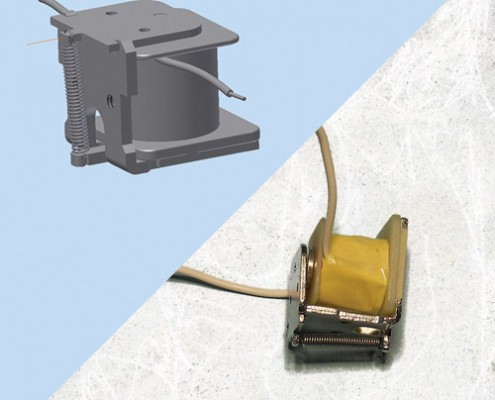

Custom Tooling

Our in-house tooling capability reduces lead time and improves productivity. From simple fixtures to fully automated assembly lines, we do it all. The laminating machine illustrated (top right) was built to process a nonstandard lamination used in a medical application. The fully automated assembly line (bottom right) was built to produce large quantities of a custom solenoid.